|

|

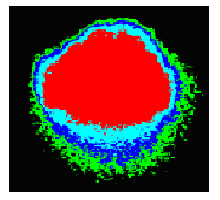

X-ray ImagingThe Fluidization Research Group is home to a unique X-ray Imaging Facility that can give quantitative real time information about the internal flow pattern of a rapidly changing three dimensional system. Over the years, The X-ray facility has been used for both academic and industrial work to study the flow phenomena and fluid-particle interactions involved in dense multiphase systems, to analyse the bubble dynamics, and how the operating conditions influence the reactor performance, efficiency and scale-up. We are able to analyse X-ray images and

provide data that allows quantifying the average fluid-bed voidage, the

voidage distribution around bubbles, to carry out the detailed analysis

of bubble dynamics and bubble hold-up, together with obtaining

expansion and deaeration profiles. X-ray imaging is also used as a

means of validation for the CFD models developed within the Group for

the simulations of multiphase systems. The FacilityThe

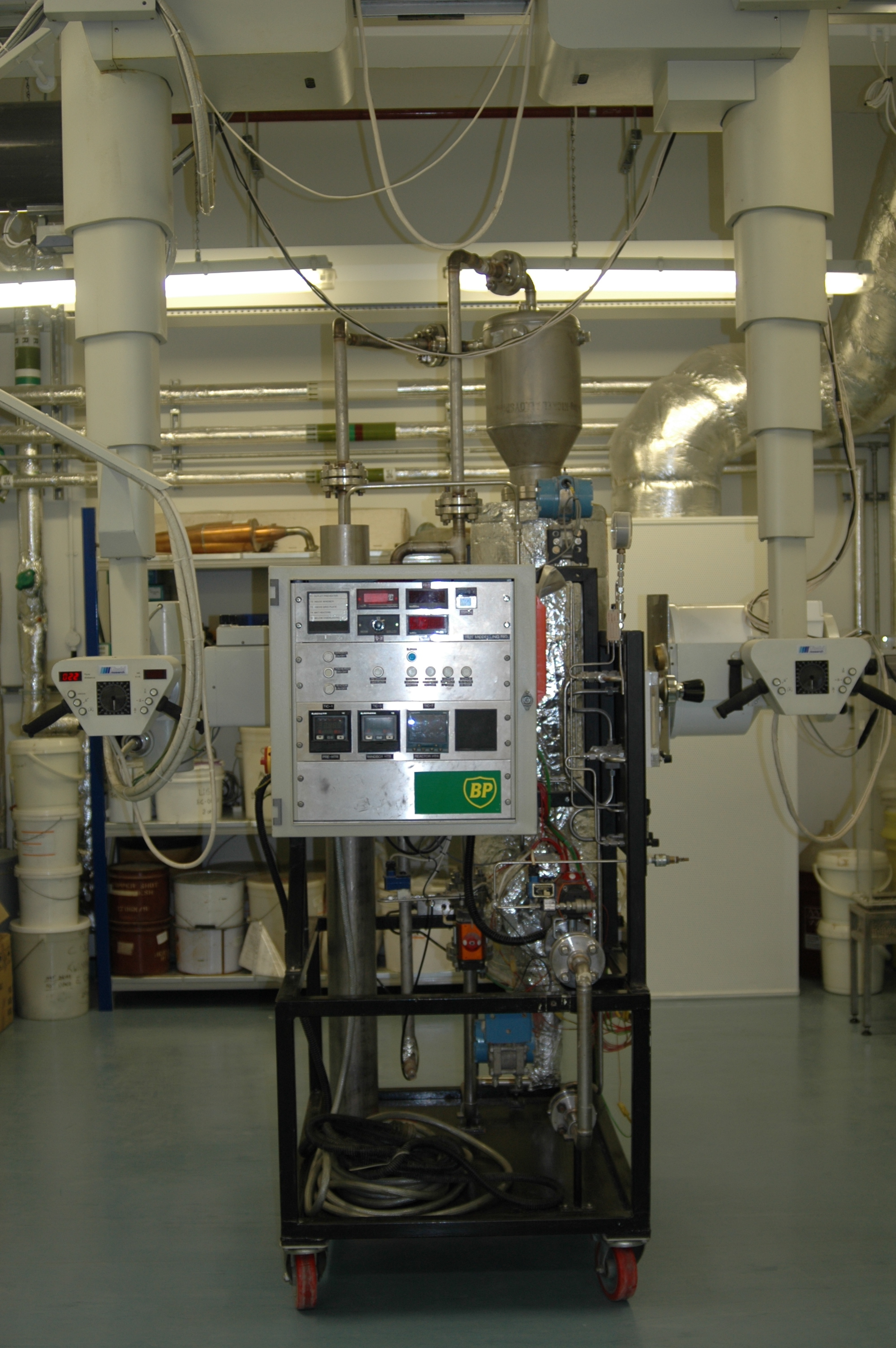

X-ray equipment is housed in a radiation proof room which contains the

X-ray generator, X-ray tube (1)

and an image intensifier (2), see Figure below. The X-ray tube and

image intensifier are mounted on a twin column ceiling suspension unit,

see (3), which allows the columns to be moved along the length of the

room. The lateral movement of each column then permits the distance

between the tube and image intensifier to be changed. Each of the

columns can also be moved in a vertical plane either independently or

synchronized as a pair. This motion is motorized and can be remotely

controlled from outside the room. A Schematic and photo of the X-ray Facility and an X-ray image of a single bubble and of a freely bubbling bed are shown below.

(Created 20 November

2007, last updated 20 February 2009)

|