|

|

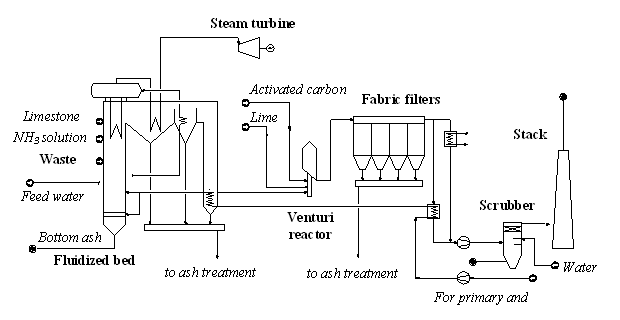

Sustainable DevelopmentEnergy from Waste and BiomassAs part of an EPSRC Sustainable Urban Environment (SUE) consortium the Group has investigated scales and technologies for sustainable urban waste management. The main objective of the work was to investigate the suitability and effectiveness of fluidized bed combustion and gasification processes for the production of energy from waste (EfW) in the urban environment. Techno-economic performance of small-to-medium scale EfW fluidized bed combustion and gasification plants coupled with steam turbine, gas engine & combined cycle gas turbine (CCGT) has been investigated for electricity and combined heat and power (CHP). The most appropriate scales for each of these plant options are evaluated in relation to system efficiencies and costs through mass and energy balances of the processes and using a discounted cash flow analysis, with the aim to make a sound judgement as to which process should be used in the urban context. In Collaboration with Advanced Plasma Power (APP), the Group is investigating the gasification of municipal solid waste coupled with plasma arc technology for the flue-gas cleaning system. Experimental and modelling kinetic analysis are conducted for the optimum design of the flue-gas systems. The Group works in collaboration with an Engineering Consulting Company in Italy to perform the design development of industrial scale EfW combustion and gasification fluidized bed plants. The Group is also involved in the process design and economic assessment of combustion and gasification plants of wood biomass and liquid biomass for the production of electric energy.

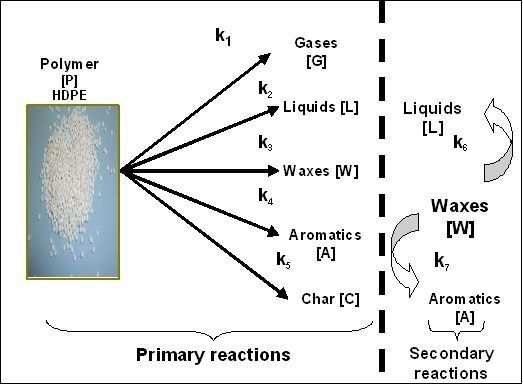

Recycling of Waste PolymersThermo-Chemical treatment (thermolysis) of virgin and waste polymers is paramount. This field of research gives an opportunity to determine thermal degradation behaviours, produce fuels from waste stream via chemical recycling schemes and create a sustainable practice out of an industrial process. To that extent, we have started using pyrolysis process on polymers to investigate the obtained products and determine the kinetic rate constant of the primary, secondary and tertiary reactions of the thermal-cracking. This leads to developing degradation models and schemes that can be utilised to design commercial scale reactors.

BiofuelsThe production of a number of key fuels and feed-stocks, such as ethanol, diesel and ethylene, can now be achieved through the processing of biomass and waste. Biomass processing is seen as being key to address the problem of global warming and reduce the use of the limited supplies of fossil-based raw materials while reducing CO2 emissions. Within this framework, we have started to investigate the feasibility of new bio-processing plants design for the production of fuels and feedstock from crop and lignocelluloses biomass. Life cycle analysis (LCA) is used to investigate all aspects of the sustainable design, including the environmental, economic and social assessment.

(Created 20 November 2007, last updated 16 March 2009) |