|

|

ExperimentalFluidization at Process ConditionsExperimental

work focuses on advancing the understanding of the mechanisms

dominating the fluidization behaviour of industrial catalysts at

process conditions and the investigation of the relative importance

between the hydro-dynamic and interparticle forces. In particular, the

effect of high temperature, presence of additives on the particles’

surface, effect of increasing the fines content and fines size

distribution on fluidization are investigated. A

small industrial scale High Temperature Fluidized bed Rig has been

developed to test powders at ambient pressure and at temperatures up to

800°C. The Rig is made in Inconel, 140mm diameter x 1000mm height, it

has a wall thickness of 3mm and is fitted with a very fine (i.e. pore

size of 20micron) stainless steel sintered distributor plate to ensure

a high pressure drop and therefore a good and even fluidization in the

bed. The upper disengaging section is fitted with a removable stainless

steel filter to reduce the loss of any elutriated fine material. Two

solenoid valves are fitted on the rig to cut the gas supply to the bed

and to vent the gas trapped in the windbox section, in order to perform

the bed collapse test. See Photograph under X-ray Imaging.

|

mechanically stirred Fluid-bed Rheometer (msFBR) |

Couette Fluid-bed Rheometer |

Thermogravimetric Analysis - Pyrolysis of waste

materials

Thermogravimetric analysis is conducted using a TGA/DSC to investigate the thermal degradation behaviour and heat flow for a number of polymers, co-polymers, powders and other materials. The analysis shows the potential of conducting pyrolysis or gasification in order to upgrade certain elements of waste into useful products and/or valuable petrochemicals. Collaboration with the industry (Ravago Plastic, Belgium) has been established on TGA assessments.

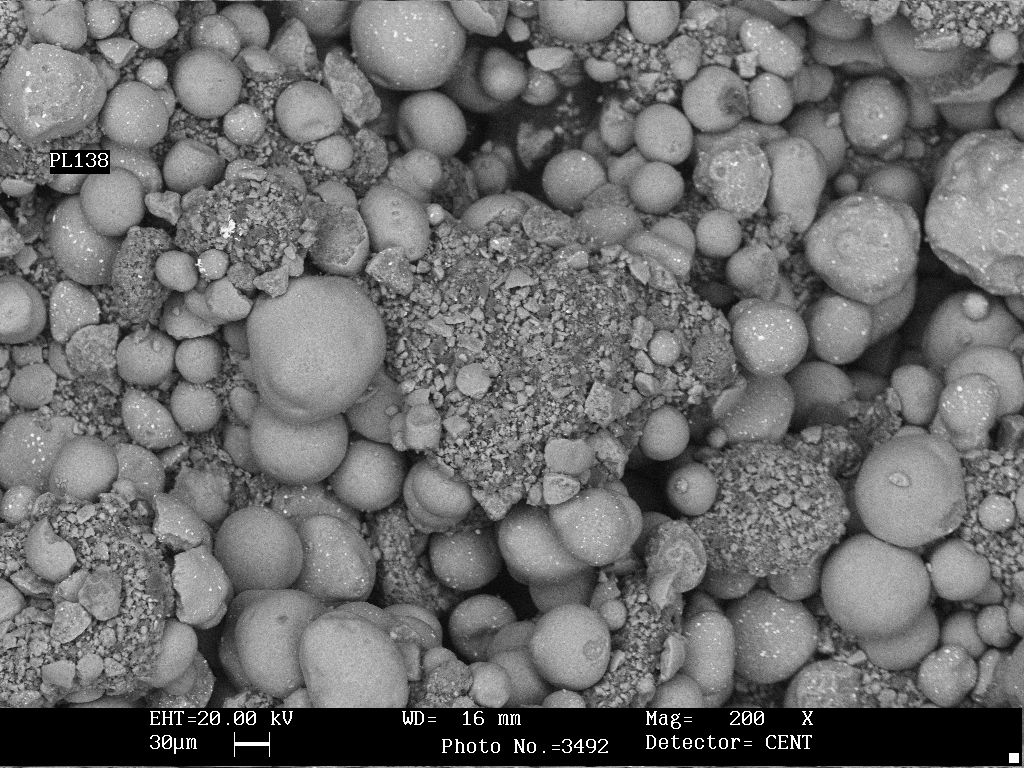

Pyroclastic Flows

Through interdisciplinary collaboration with the Laboratoire Magmas et Volcanos of the University Blaise Pascal in Clermont-Ferrand in France the Group is studying the fluid-mechanics of pyroclastic flows generated during explosive volcanic eruptions. Volcanic materials are fluidized at high temperature and X-rays are used to explain the ability of pyroclastic flows to maintain high gas pore pressure, and hence low friction, during run-out.

(Created 20 November 2007, last updated 20 February 2009)