E S Fraga: Jacaranda blog

Table of Contents

Introduction

This document presents a collection of notes and news items for the Jacaranda system for automated design and optimisation sorted in reverse chronological order.

Visit my home pages for links to my pages on general research, teaching and other interests.

Direct flowsheet definition

Although Jacaranda was explicitly created for the automated design of processes, including heat exchanger networks, there are times when one may wish to investigate the behaviour of a particular given process. Jacaranda provides a Flowsheet class for just this purpose. An instance of this class can be defined directly by the engineer or as the result of an automated design run in Jacaranda. This blog entry will focus on the user defined case.

A flowsheet consists of a set of units and their connections. Connections are represented by streams. To define a flowsheet, we first define the units and the streams and finally tell Jacaranda how they come together.

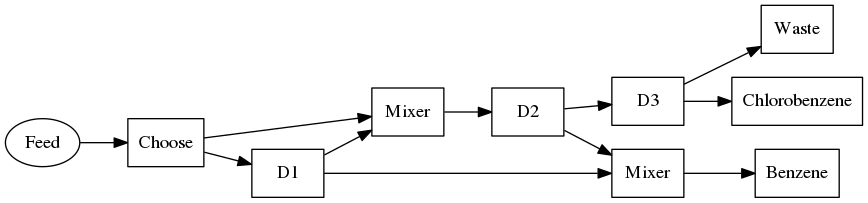

The following is an example of a superstructure flowsheet. A superstructure is a representation of multiple structures and is the basis for alternative automated design procedures, often through the use of generic MINLP solvers such as those available through GAMS. Jacaranda also has a range of MINLP solvers, mostly based on stochastic optimisation methods but also direct search methods.

The superstructure consists of three distillation units. A valid process in this example could consist of just two distillation units but a three distillation unit process is actually less expensive to operate under specific conditions. It is worth exploring the trade-offs between the two options through the use of a single superstructure Flowsheet object.

We consider the separation of a mixture which is actually the output of a reaction unit used for the chlorination of benzene. The feed to the separation section is 97% Benzene (component A below), 1% C6H5Cl (B), 1% p-C6H4Cl2 (C), and 1% C6H3Cl3 (D). The aim is produce pure Benzene (>98% purity) and somewhat pure C6H5Cl (>90% purity). The other two components are waste products and come out with any purity. We want less than 1% of any of the waste products in the Benzene output stream. Short cut design methods based on the Fenske-Underwood-Gilliland model.

The rest of this blog entry is a description of the input file for this process. We start with some general settings:

# start by specifying that all objects come from the Jacaranda

# package, specifically the process synthesis sub-package and the unit

# models. We turn on assertions to catch any silly errors as we are

# still debugging some of this code

use jacaranda.design.ps

use jacaranda.design.units

# define some global variables

variables

# the discretization of component flows

const Base 0.001 "Base component flow discretization"

# define the flows of the components in the feed

const Fbenzene 0.97 "Flow of Benzene in feed stream"

const Fc6h5cl 0.01 "Flow of C6H5Cl in feed stream"

const Fpc6h4cl2 0.01 "Flow of p-C6H4Cl2 in feed stream"

const Fc6h3cl3 0.01 "Flow of C6H3Cl3 in feed stream"

# set the cost base to 1993 based on the M&S index

set msindex 964.2

# and the number of discrete enthalpy (or state) levels for streams.

# it is probably a good idea to have this value match the number of

# operating pressures in the distillation columns.

const nPs 4 "Number of discrete stream enthalpy levels"

end

# define the ranking criteria: we want to study the difference in

# operating versus capital costs so we define two criteria, each of

# which is the sum of the relevant criterion value generated by each

# unit in a flowsheet. The term in quotes for each criterion is the

# expression to evaluate for each unit. The "sum" means that the value

# of the criterion is the sum of expression evaluate for all the units

# in the resulting flowsheets.

Criteria costs

criterion CapitalCost sum "capcost"

criterion OperatingCost sum "opercost"

end

# define the heat exchanger model for heating and cooling. We define

# two cost functions, one for the capital cost as a function of the

# area of the exchanger, and the other the operating cost as a

# function of the duty (Q [kJ]), the cost of the utility used (Cu

# [$/kJ]), and the time (seconds in a year equal to h*hpy where hpy is

# the "hours per year"). To cater for equal temperature differences at

# both ends of the exchanger, we use the Chen approximation.

HeatExchanger hex

model

deltain = abs(T1in-T2out)

deltaout = abs(T1out-T2in)

eps = abs(deltain/deltaout-1)

if eps < 4e-4

lmtd = (1+eps/2-eps^2/12)*deltaout

else

lmtd = (deltain - deltaout)/log(deltain/deltaout)

endif

A = Q/U/lmtd

capcost = 101964 + 92.9*A^0.65

opercost = Cu*Q*h*hpy

end

end

# define the utilities available for meeting heating and cooling

# demands from the units. the parameters for each unit are inlet

# temperature, outlet temperature, heat transfer coefficient, and

# cost.

DiscreteUtilities utils

hot "Steam @ 28.23 atm" 503.5 503.5 "5000 *W/m^2/K" "1.0246 / GJ"

hot "Steam@11.22atm" 457.6 457.6 "5000 *W/m^2/K" "0.773824 / GJ"

hot "Steam@4.08atm" 417.0 417.0 "5000 *W/m^2/K" "0.573203 / GJ"

hot "Steam@1.70atm" 388.2 388.2 "5000 *W/m^2/K" "0.41796 / GJ"

cold "ColdWater@32.2degC" 305.2 305.2 " 500 *W/m^2/K" "0.0668737 / GJ"

cold "Ammonia@1degC" 274.00 274.00 " 500 *W/m^2/K" "1.65035 / GJ"

cold "Ammonia@-17.68degC" 255.32 255.32 " 500 *W/m^2/K" "2.96871 / GJ"

cold "Ammonia@-21.67degC" 251.33 251.33 " 500 *W/m^2/K" "3.96226 / GJ"

end

# all the data we need for this problem has been defined. Now set the

# global data variables that are used by the synthesis procedure

# before attempting to define the actual synthesis problem.

Data

criteria costs # rank according to given criteria

hex hex # use heat exchanger model specified

utils utils

print # output all settings

end

With these setting, we can now proceed to define the flowsheet. The first requirement is the definition of the feed stream. This requires us to define the species that appear in the process along with the data required for the estimation of the necessary physical properties, such as bubble and dew points for mixtures.

vle.KistaComponent benzene bp 353.2 cpv -33.917 4.743e-1 -3.017e-4 7.130e-8 lhtc " 500 *W/m^2/K" vhtc "5000 *W/m^2/K" end vle.KistaComponent C6H5Cl bp 405.2 cpv -33.888 5.631e-01 -4.521e-04 1.426e-07 lhtc " 500 *W/m^2/K" vhtc "5000 *W/m^2/K" end vle.KistaComponent p-C6H4Cl2 bp 447.3 cpv -14.344 5.534e-01 -4.559e-04 1.447e-07 lhtc " 500 *W/m^2/K" vhtc "5000 *W/m^2/K" end vle.KistaComponent C6H3Cl3 bp 486.2 cpv -14.361 6.087e-01 -5.622e-04 2.072e-07 lhtc " 500 *W/m^2/K" vhtc "5000 *W/m^2/K" end

With the components known, we can define the stream as a single liquid phase. The phase composition is defined using the quantities defined earlier. It is also useful to define the base discretisation values although these are not strictly necessary for process simulation and optimisation.

vle.Phase feedPhase add benzene Fbenzene add C6H5Cl Fc6h5cl add p-C6H4Cl2 Fpc6h4cl2 add C6H3Cl3 Fc6h3cl3 base benzene "Base * Fbenzene" base C6H5Cl "Base * Fc6h5cl" base p-C6H4Cl2 "Base * Fpc6h4cl2" base C6H3Cl3 "Base * Fc6h3cl3" end vle.Stream feed add feedPhase nstates nPs T 313 P "1 *atm" print end

We are now ready to define the units of the process. We start with the feed tank and the product tanks. The latter include the specification constraints that ensure the process designed meets the requirements.

vle.FeedTank feedtank Stream feed feed end # the tops of the first distillation will go into a tank for pure # benzene hopefully. The benzene is destined to be recycled back to # the reaction section. We want at least 98% purity and no more than # 0.005 kmol/s of Chlorobenzene. vle.ProductTank pureBenzene Expression spec "(x[benzene]>0.98) & (F*x[C6H5Cl] < 0.005)" end # We require a purity of Chlorobenzene of at least 90%. vle.ProductTank pureC6H5Cl Expression spec "x[C6H5Cl]>0.90" end # finally, the product tank that accepts waste streams: Any other # stream which has a composition of less than 10% Benzene and 10% # Chlorobenzene is allowed as a waste stream. vle.ProductTank otherProducts Expression spec "(x[benzene]<0.10) & (x[C6H5Cl]<0.10)" end

The processing units are three distillation columns. Each of them has a number of design variables which define the search space for the optimisation procedure. These include the reflux rate factor. rrf, the tray efficiency and the key recovery.

# the first distillation unit has benzene as the light key vle.Distillation dist-1 Component key benzene Real rrf 1.2 1.05 1.5 10 Real trayefficiency 1.0 1.0 1.0 1 Boolean eduljee false Boolean conceptual false Boolean sfa false Boolean totalcondenser true new tunable+specification "Recovery of light and heavy keys" Real rec 0.95 0.800 0.999 10 LogReal P 5.039684199579494 1.0 32.0 16 end # the second distillation unit has benzene as the light key as well. vle.Distillation dist-2 Component key benzene Real rrf 1.2 1.05 1.5 10 Real trayefficiency 1.0 1.0 1.0 1 Boolean eduljee false Boolean conceptual false Boolean sfa false Boolean totalcondenser true new tunable+specification "Recovery of light and heavy keys" Real rec 0.999 0.800 0.999 10 LogReal P 2.0 1.0 32.0 16 end # The next distillation column separates the actual product # (Chlorobenzene) from the waste products. vle.Distillation dist-3 Component key C6H5Cl Real rrf 1.2 1.05 1.5 1 Real trayefficiency 1.0 1.0 1.0 1 Boolean eduljee false Boolean conceptual false Boolean sfa false Boolean totalcondenser true new tunable+specification "Recovery of light and heavy keys" Real rec 0.95 0.800 0.999 10 LogReal P 1.5874010519681996 1.0 32.0 16 end

The remaining units are used to define the superstructure. We have on option: the first distillation unit performs the same separation as the second one. Do we want to use two units, at lower recoveries for the keys, or a single high recovery unit? To define the superstructure, we introduce a Chooser unit which sends the feed either to the first distillation unit or to the second one. To process the outputs, we define two mixers as well.

# there is a choice immediately which is whether the feed goes to the # first distillation unit or skips it and goes to the second # distillation unit. vle.Chooser chooser Int choice 1 0 1 1 end # associated with the chooser is a mixer which will be used to specify # the feed to the second distillation unit as being from the feed tank # or from the bottoms output of the first distillation unit vle.Mixer choiceMixer Boolean allownull true end vle.Mixer benzeneMixer Boolean allownull true end

Everything has now been defined. We can specify the flowsheet structure. This will consist from a number of lines where each line has a from unit and a number of to units. Each of the output streams of the from unit is sent as an input stream to one of the to units.

Flowsheet clben

build

feedtank chooser

chooser dist-1 choiceMixer

dist-1 benzeneMixer choiceMixer

choiceMixer dist-2

dist-2 benzeneMixer dist-3

benzeneMixer pureBenzene

dist-3 pureC6H5Cl otherProducts

end

continuous

evaluationmethod breadthfirst

evaluate

print

end

The full input file is here:

# input file for the optimization problem post-synthesis for the

# Chlorobenzene separation problem. The structure is actually a

# superstructure which will allow us to choose between a 2 unit

# solution and a 3 unit solution. The latter allows for lower

# recovery in some distillation units. The aim of this input file is

# to provide an objective function for optimization of three sets of

# variables for the distillation columns in the process flowsheet: the

# operating pressure, the reflux rate factor and the recovery as well

# as a binary variable for choosing the first unit in the sequence.

# Copyright (c) 2005-2014, Eric S Fraga, All rights reserved.

project 2or3 # name will be used for report generation

# start by specifying that all objects come from the Jacaranda

# package, specifically the process synthesis sub-package and the unit

# models.

use jacaranda.design.ps

use jacaranda.design.units

# define some global variables

variables

# the discretization of component flows

const Base 0.001 "Base component flow discretization"

# define the flows of the components in the feed

const Fbenzene 0.97 "Flow of Benzene in feed stream"

const Fc6h5cl 0.01 "Flow of C6H5Cl in feed stream"

const Fpc6h4cl2 0.01 "Flow of p-C6H4Cl2 in feed stream"

const Fc6h3cl3 0.01 "Flow of C6H3Cl3 in feed stream"

# set the cost base to 1993 based on the M&S index

set msindex 964.2

# and the number of discrete enthalpy (or state) levels for streams.

# it is probably a good idea to have this value match the number of

# operating pressures in the distillation columns.

const nPs 4 "Number of discrete stream enthalpy levels"

end

# define the ranking criteria: we want to study the difference in

# operating versus capital costs so we define two criteria, each of

# which is the sum of the relevant criterion value generated by each

# unit in a flowsheet. The term in quotes for each criterion is the

# expression to evaluate for each unit. The "sum" means that the value

# of the criterion is the sum of expression evaluate for all the units

# in the resulting flowsheets.

Criteria costs

criterion CapitalCost sum "capcost"

criterion OperatingCost sum "opercost"

end

# define the heat exchanger model for heating and cooling. We define

# two cost functions, one for the capital cost as a function of the

# area of the exchanger, and the other the operating cost as a

# function of the duty (Q [kJ]), the cost of the utility used (Cu

# [$/kJ]), and the time (seconds in a year equal to h*hpy where hpy is

# the "hours per year"). To cater for equal temperature differences at

# both ends of the exchanger, we use the Chen approximation.

HeatExchanger hex

model

deltain = abs(T1in-T2out)

deltaout = abs(T1out-T2in)

eps = abs(deltain/deltaout-1)

if eps < 4e-4

lmtd = (1+eps/2-eps^2/12)*deltaout

else

lmtd = (deltain - deltaout)/log(deltain/deltaout)

endif

A = Q/U/lmtd

capcost = 101964 + 92.9*A^0.65

opercost = Cu*Q*h*hpy

end

end

# define the utilities available for meeting heating and cooling

# demands from the units. the parameters for each unit are inlet

# temperature, outlet temperature, heat transfer coefficient, and

# cost.

DiscreteUtilities utils

hot "Steam @ 28.23 atm" 503.5 503.5 "5000 *W/m^2/K" "1.0246 / GJ"

hot "Steam@11.22atm" 457.6 457.6 "5000 *W/m^2/K" "0.773824 / GJ"

hot "Steam@4.08atm" 417.0 417.0 "5000 *W/m^2/K" "0.573203 / GJ"

hot "Steam@1.70atm" 388.2 388.2 "5000 *W/m^2/K" "0.41796 / GJ"

cold "ColdWater@32.2degC" 305.2 305.2 " 500 *W/m^2/K" "0.0668737 / GJ"

cold "Ammonia@1degC" 274.00 274.00 " 500 *W/m^2/K" "1.65035 / GJ"

cold "Ammonia@-17.68degC" 255.32 255.32 " 500 *W/m^2/K" "2.96871 / GJ"

cold "Ammonia@-21.67degC" 251.33 251.33 " 500 *W/m^2/K" "3.96226 / GJ"

end

# now define the actual process flowsheet which consists of three

# distillation columns and four specific product tanks, as well as a

# feed tank!

# the first unit is the feed tank for which we also need to define the

# actual feed stream. This stream consists of the output of

# the reactor and there are 4 different components. All the components

# of the stream are defined using the KistaComponent class. This

# component class uses physical properties estimation methods based on

# the 1 atm boiling point of the component and the coefficients of the

# vapour heat capacity polynomial correlation (available from most

# good chemical engineering resource books...). The component

# definitions include the specification of the smallest amount of that

# component that can be represented in the discrete space used by the

# Jacaranda search procedure. These minimum amounts are based on the

# feed stream amount multiplied by a base discretization value,

# defined above.

vle.KistaComponent benzene

bp 353.2

cpv -33.917 4.743e-1 -3.017e-4 7.130e-8

lhtc " 500 *W/m^2/K"

vhtc "5000 *W/m^2/K"

end

vle.KistaComponent C6H5Cl

bp 405.2

cpv -33.888 5.631e-01 -4.521e-04 1.426e-07

lhtc " 500 *W/m^2/K"

vhtc "5000 *W/m^2/K"

end

vle.KistaComponent p-C6H4Cl2

bp 447.3

cpv -14.344 5.534e-01 -4.559e-04 1.447e-07

lhtc " 500 *W/m^2/K"

vhtc "5000 *W/m^2/K"

end

vle.KistaComponent C6H3Cl3

bp 486.2

cpv -14.361 6.087e-01 -5.622e-04 2.072e-07

lhtc " 500 *W/m^2/K"

vhtc "5000 *W/m^2/K"

end

# using these components, define the feed stream as a single phase at specified

# temperature and pressure. First define the phase object with the

# correct amounts of each component.

vle.Phase feedPhase

add benzene Fbenzene

add C6H5Cl Fc6h5cl

add p-C6H4Cl2 Fpc6h4cl2

add C6H3Cl3 Fc6h3cl3

# also define the granularity of the component flows for each

# component. This is the basic discretization used by Jacaranda to

# ensure that the search graph generated implicitly is finite in

# size. The granularity should be appropriate for the particular

# problem and, in particular, should be consistent with

# discretizations performed in the separation units (for example) and

# the product specifications. In this problem, we have specified the

# same discretization factor ("Base" as defined in the main input

# file) for each component as a function of its flow in the feed

# stream. The individual flows of the components in the feed stream

# have been defined in the main input file as well.

base benzene "Base * Fbenzene"

base C6H5Cl "Base * Fc6h5cl"

base p-C6H4Cl2 "Base * Fpc6h4cl2"

base C6H3Cl3 "Base * Fc6h3cl3"

# output information about this phase object which will include the

# component discretizations defined above

show

end

# The stream definition includes, as well as the main phase object

# defined above, the specification of the initial temperature and

# pressure and the number of discrete pressure levels which can be

# represented. This number, nPs, is defined in the main input file.

vle.Stream feed

add feedPhase

nstates nPs

T 313

P "1 *atm"

print

end

# finally define the actual feed tank which will output the stream

# defined immediately above

vle.FeedTank feedtank

Stream feed feed

end

# there is a choice immediately which is whether the feed goes to the

# first distillation unit or skips it and goes to the second

# distillation unit.

vle.Chooser chooser

Int choice 1 0 1 1

end

# associated with the chooser is a mixer which will be used to specify

# the feed to the second distillation unit as being from the feed tank

# or from the bottoms output of the first distillation unit

vle.Mixer choiceMixer

Boolean allownull true

end

vle.Mixer benzeneMixer

Boolean allownull true

end

# the first distillation unit has benzene as the light key

jacaranda.design.units.vle.Distillation dist-1

Component key benzene

Real rrf 1.2 1.05 1.5 10

Real trayefficiency 1.0 1.0 1.0 1

Boolean eduljee false

Boolean conceptual false

Boolean sfa false

Boolean totalcondenser true

new tunable+specification "Recovery of light and heavy keys" Real rec 0.95 0.800 0.999 10

LogReal P 5.039684199579494 1.0 32.0 16

end

# the tops of the first distillation will go into a tank for pure

# benzene hopefully. The benzene is destined to be recycled back to

# the reaction section. We want at least 98% purity and no more than

# 0.005 kmol/s of Chlorobenzene.

jacaranda.design.units.vle.ProductTank pureBenzene

Expression spec "(x[benzene]>0.98) & (F*x[C6H5Cl] < 0.005)"

end

# the second distillation unit has benzene as the light key as well.

jacaranda.design.units.vle.Distillation dist-2

Component key benzene

Real rrf 1.2 1.05 1.5 10

Real trayefficiency 1.0 1.0 1.0 1

Boolean eduljee false

Boolean conceptual false

Boolean sfa false

Boolean totalcondenser true

new tunable+specification "Recovery of light and heavy keys" Real rec 0.999 0.800 0.999 10

LogReal P 2.0 1.0 32.0 16

end

# The next distillation column separates the actual product

# (Chlorobenzene) from the waste products.

jacaranda.design.units.vle.Distillation dist-3

Component key C6H5Cl

Real rrf 1.2 1.05 1.5 1

Real trayefficiency 1.0 1.0 1.0 1

Boolean eduljee false

Boolean conceptual false

Boolean sfa false

Boolean totalcondenser true

new tunable+specification "Recovery of light and heavy keys" Real rec 0.95 0.800 0.999 10

LogReal P 1.5874010519681996 1.0 32.0 16

end

# We require a purity of Chlorobenzene of at least 90%.

jacaranda.design.units.vle.ProductTank pureC6H5Cl

Expression spec "x[C6H5Cl]>0.90"

end

# finally, the product tank that accepts waste streams: Any other

# stream which has a composition of less than 10% Benzene and 10%

# Chlorobenzene is allowed as a waste stream.

jacaranda.design.units.vle.ProductTank otherProducts

Expression spec "(x[benzene]<0.10) & (x[C6H5Cl]<0.10)"

end

# all the data we need for this problem has been defined. Now set the

# global data variables that are used by the synthesis procedure

# before attempting to define the actual synthesis problem.

Data

criteria costs # rank according to given criteria

hex hex # use heat exchanger model specified

utils utils

print # output all settings

end

# all the units have been defined so we can create the actual process

# flowsheet.

jacaranda.design.ps.Flowsheet clben

build

feedtank chooser

chooser dist-1 choiceMixer

dist-1 benzeneMixer choiceMixer

choiceMixer dist-2

dist-2 benzeneMixer dist-3

benzeneMixer pureBenzene

dist-3 pureC6H5Cl otherProducts

end

continuous

evaluationmethod breadthfirst

evaluate

print

end

Optimisation with external models

In the previous blog entry, I described how Jacaranda has been extended to allow models to be written in other languages, specifically in GAMS. Octave is also supported. This blog entry shows how these models can be used by the optimisation methods implemented within Jacaranda. An example employing the basic genetic algorithm is presented.

The key to using a model written in an external modelling system is

the definition of an object which instantiates the

ModelBasedObjectiveFunction class. The following example uses the external

gams model which defines a MINLP described by Westerlund & Westerlund

(2003).

use jacaranda.util.opt

ModelBasedObjectiveFunction model

model gams

code westerlund.gms # the base gams model code

name westerlund # the GAMS model to use

command "/opt/gams/22.8/gams" # how to run gams on this system

# next two lines initialise GAMS variables x and y

# from Jacaranda's own x (continuous) and y (integer) variables

# defined by the Jacaranda model object

in x[0] x.fx

in y[0] y.fx

# the final value of the z GAMS variable will be copied

# back into Jacaranda's z variable

out z.l z

# define the task for GAMS

objective "solve westerlund using minlp minimizing z"

result "z" # what to return upon evaluation

end

# lower and upper bounds

a 1 1 # lower bound on both x and y variables

b 6 6 # and upper bound as well

# evaluate/solve the model using x=1.1 and y=1 as initial

# values and return the criteria values (z in our case)

evaluate 1.1 1

print

show

end

This objective function instance will make use of an external model

written using the GAMS modelling language and will be solved using

GAMS. This optimisation problem has one real variable (x[0] in

Jacaranda's own modelling language) and one integer variables (y[0]

in Jacaranda) which map to x and y in GAMS. In the GAMS model,

these variables are fixed and the model in GAMS is a square

system. The result of the GAMS solution will be in z which is copied

back to the same named variable in Jacaranda.

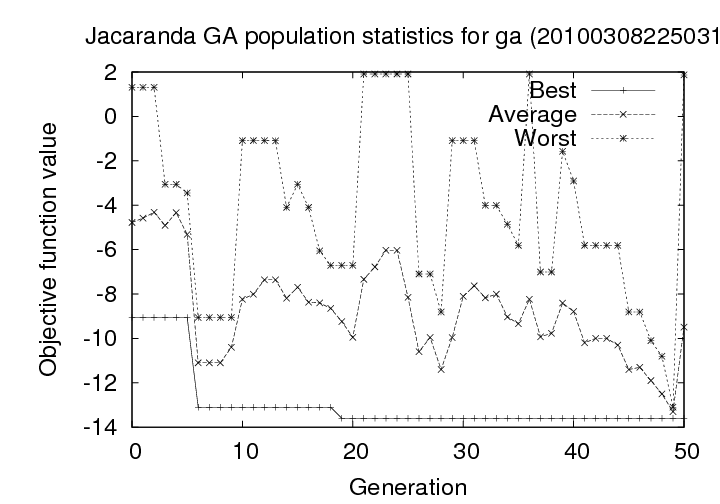

Once defined as an objective function, it can be used anywhere in Jacaranda where an objective function is allowed. This includes, for instance, the genetic algorithm classes. The evolution of the solutions obtained by this genetic algorithm for this problem is illustrated in this figure:

Figure 1: Statistics for population as it evolves under the control of a genetic algorithm

The commands to generate this plot are created automatically by Jacaranda and placed in the org-mode formatted output file.

External models in Jacaranda

Every object in the Jacaranda system can have a model associated with it. By default, these models are written in the Jacaranda Expression language. This language supports vector based arithmetic but is essentially a calculator. Sometimes, a more powerful modelling language is required.

Jacaranda has been extended to allow the use of external modelling systems. A framework has been put in place. At the moment, only one external language interface has been defined: for the GAMS modelling system. With this interface, a model can be written in GAMS and Jacaranda can communicate with GAMS to transfer values into GAMS and back out again.

A small GAMS modelling example

Consider the following Jacaranda input file:

use jacaranda.base

define

variable x1upper 2.5 # this will be used to set a GAMS value below

end

EGO gamsmodel

model gams

code test.gms # where the base gams model code is

command "/opt/gams/22.8/gams" # how to run gams on this system

# use x1upper Jacaranda variable to set GAMS variable X1.UP

in x1upper X1.UP

# and take result from GAMS of z and place in Jacaranda's z value

out z.l z

objective "solve test using nlp minimizing z"

result z # evaluate this expression to generate result

end

evaluatemodel # do it!

print

end

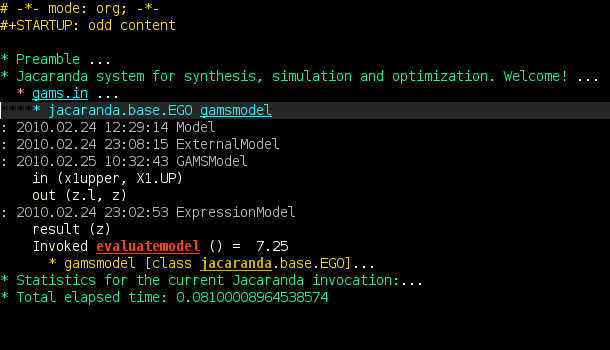

This example creates a simple object which defines the model

associated with the object as being an external GAMS model. The GAMS

model is in the file test.gms and includes everything but the actual

solve directive. The solve directive is specified by the

objective statement in Jacaranda.

The test code for this example is here:

$TITLE Test Problem $OFFSYMXREF $OFFSYMLIST * Example from Problem 8.26 in "Engineering Optimization" * by Reklaitis, Ravindran and Ragsdell (1983) * Code from * http://www.che.boun.edu.tr/courses/che477/gms-mod.html#TEST.GMS * (from a course by Ignacio Grossmann) VARIABLES X1, X2, X3, Z ; POSITIVE VARIABLES X1, X2, X3 ; EQUATIONS CON1, CON2, CON3, OBJ ; CON1.. X2 - X3 =G= 0 ; CON2.. X1 - X3 =G= 0 ; CON3.. X1 - X2**2 + X1*X2 - 4 =E= 0 ; OBJ.. Z =E= SQR(X1) + SQR(X2) + SQR(X3) ; * Upper bounds X1.UP = 5 ; X2.UP = 3 ; X3.UP = 3 ; * Initial point X1.L = 4 ; X2.L = 2 ; X3.L = 2 ; MODEL TEST / ALL / ; OPTION LIMROW = 0; OPTION LIMCOL = 0;

The Jacaranda input defines a new value for the upper bound on X1

and the result of evaluating the model is the value of the z

variable, specifically the level of that variable, z.l. The in

and out directives specify how to bring values in to the model

from Jacaranda and then back out again.

The output from Jacaranda, in org-mode in Emacs, can be seen here:

where we can see that the result of solving the GAMS model is 7.25.

This is actually a higher value than the optimum because we have

restricted variable X1 to a smaller upper bound, to illustrate the

transfer of values from Jacaranda to GAMS, and the optimum lies above

this upper bound.

The result can be any expression and not just a single variable. The

expression uses Jacaranda's own modelling language but has access to

any variables exported from the GAMS model (z.l in this case). Any

number of variables can be imported into the GAMS model and any number

exported as well.

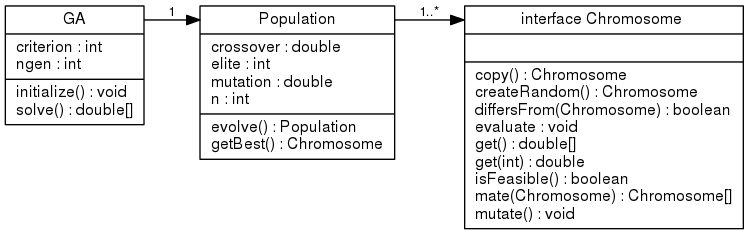

The Genetic Algorithm classes

One of the built-in optimisation tools in the Jacaranda system is based on genetic algorithms. This short note describes the layout of the relevant classes and illustrates their use with a simple MINLP problem. The aim is not only to illustrate their use but also to explain how these classes can be extended or used directly to build new targeted genetic algorithm solution methods.

All classes and interfaces described in this section are in the

jacaranda.util.opt package unless stated otherwise.

The GA classes in Jacaranda

The following figure shows the three base classes which make up the genetic algorithm system. The GA class is the main controlling class. It will have a single population which must be provided during the definition of an instance of the GA object. The population will consist of a set of chromosomes, with the initialisation requiring the provision of a single chromosome to seed the population. The population may also be given diversity and selection objects which are discussed below. The chromosome is an interface; there is at least one base implementation, also described below, but it is through defining a new chromosome implementation that the method can be tailored for specific problems.

Figure 2: Base class hierarchy for the Genetic Algorithm procedure in Jacaranda

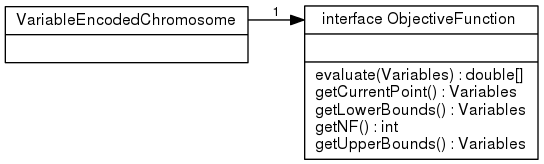

An implementation of the Chromosome interface,

VariableEncodedChromosome, is available in Jacaranda, suitable for

general MINLP (mixed integer nonlinear programme) problems. These

problems are defined by a combination of real and integer decision or

optimisation variables, one or more objective functions, possibly

constraint equations, both equality and inequality, and bounds on the

decision variables. This general Chromosome implementation is

actually more general than this and is suitable for any object that

can be encoded into and decoded from a combination of real and integer

variables but whose fitness can be evaluated through an objective

function object.

Figure 1: Variable encoded chromosome uses an objective function object for evaluation

The mate and mutate methods use appropriate operations for MINLP

problems. Specifically, the crossover operation is based on a

multi-point crossover across both real and integer variables. The

mutation operator selects on variable, randomly from the set of both

real and integer variables, and gives it a new value randomly from the

domain for that variable. These operators are actually implemented by

the Encoding implementation. The default encoding used by the

VariableEncodedChromosome is the GeneralEncoding class.

Alternative encodings include the BoundaryMutationEncoding, which

replaces the mutation operation with one which emphasises a move to

the boundaries for the selected variable, and the BinaryEncoding,

which encodes each real and integer value in a prespecified number of

bits for each variable.

The NLP and MINLP classes implement the ObjectiveFunction

interface and provide the ability to define the actual objective

functions (Jacaranda support multi-objective optimisation fully),

equality and inequality constraints and the lower and upper bounds on

the decision variables.

An MINLP example

1 use jacaranda.util.opt

2

3 echo "----------------------------------------------- Objective function"

4 MINLP model

5 # objective function with both real, x, and integer, y, variables

6 f "(x[0]-5)^2+(x[1]-3)^2-y*sqrt($x)"

7 # inequality contraints.

8 g "{ 2-(x[0]+x[1]), (x[0]+x[1])-10 }"

9 # lower and upper bounds

10 a "{0, 0}" "0"

11 b "{10, 10}" "1"

12 end

13

14 echo "----------------------------------------------- Chromosome"

15 VariableEncodedChromosome var

16 function model

17 end

18

19 echo "----------------------------------------------- Selection"

20 RouletteSelection roulette

21 end

22

23 echo "----------------------------------------------- Population"

24 Population pop

25 chromosome var

26 crossover 0.75

27 elite 1

28 mutation 0.02

29 n 20

30 selection roulette

31 end

32

33 echo "----------------------------------------------- GA"

34 GA ga

35 outputlevel 2

36 population pop

37 ngen 50

38 solve

39 print

40 end

Octave interface to Jacaranda

Octave can be used with Jacaranda for access to more powerful or specific optimisation and data analysis methods. A new interface for Jacaranda from Octave has been defined.

Introduction

An interface to Jacaranda from Octave (a tool similar to, and often very compatible with, Matlab) is potentially very useful, especially in the context of optimisation. Jacaranda provides a framework for process definitions, including simple or complex physical properties and processing units. Although Jacaranda has a number of optimisation methods included, it is not meant to be all-encompassing. As much of the optimisation research world-wide uses Octave or Matlab, an interface from Octave (due to its open source nature in preference to the proprietary and closed source Matlab) can be useful.

Previous versions of Jacaranda have included such an interface. However, the interface was based on the use of socket communication which could be slow when many objective function evaluations were required. It was also not a very portable solution which, although not often an issue (Jacaranda runs well on almost any Linux distribution), there is not reason to be limiting in portability.

Recently, a generic interface from Octave to Java has been implemented by Michael Goffioul. Jacaranda has therefore been updated to make use of this interface as it provides a much more elegant solution than what Jacaranda had before and is also more efficient.

An example

The full Jacaranda distribution (provided to collaborators) includes an input file which demonstrates this interface. As the more general distribution does not include this particular input file, I include it here for illustration:

1 ## Test out the Octave Java interface to Jacaranda.

2 ##

3 ## Eric S Fraga

4 function jacaranda_test

5 persistent version;

6 if (isempty(version))

7 version = "2008.08.05 23:55:43";

8 printf ("ESF %s, Octave java to Jacaranda function evaluation\n", version)

9 endif

10 ## initialise the Jacaranda interface from Octave, using a test input

11 ## file which defines an appropriate objective function. The

12 ## particular example, from Rathore et al (1974) is the design of a

13 ## heat integrated distillation sequence. The input file will

14 ## generate at least one flowsheet design. This flowsheet will define

15 ## an objective function with 8 real optimisation variables and 3

16 ## criteria for optimisation.

17 ##

18 ## Note that the following assumes that the Jacaranda class files are

19 ## stored in the given location relative to this file and that,

20 ## therefore, Octave has been started in this directory.

21 [A B nx ny nf] = jacaranda_init ("../vle/rathore_hen.in", \ # input file

22 "rathore_hen-1-1", \ # objective function

23 "../../src/java") # Jacaranda classpath

24 ## now evaluate the flowsheet at a number of random points

25 N = 100;

26 Y = [];

27 n_infeasible = 0;

28 for i=1:N

29 x = A + rand(1,length(A)).*(B-A);

30 try

31 y = jacaranda_evaluate (x);

32 Y = [Y; y];

33 catch

34 n_infeasible++;

35 end_try_catch

36 endfor

37 if n_infeasible > 0

38 printf ("There were %d infeasible design points (out of %d total) found.\n", n_infeasible, N);

39 endif

40 printf ("Minimum criteria values: %8.2e %8.2e %8.2e\n", min(Y));

41 printf ("Maximum criteria values: %8.2e %8.2e %8.2e\n", max(Y));

42 ## the results obtained above are plotted to give some indication of

43 ## the variation in the three criteria for random design points

44 plot (Y);

45 endfunction

I believe the comments describe clearly what is happening so I will leave it at this for now.

Defining simple unit models in Jacaranda

Simple unit models can be written using the Unit class in Jacaranda

with the equations written in the expr expression evaluator

available in Jacaranda.

Introduction

Although the Jacaranda system comes with a number of pre-defined process unit models (e.g. Distillation), there are many problems in conceptual design that only require simple models. These simple models may not require complex physical property values and may consist of, for instance, idealised mass and energy balances. For these cases, it may be worthwhile to define ad hoc simple models.

Jacaranda provides a generic model for such cases: units.Unit [1],

intended for use with streams supporting vapour liquid equilibria

properties (although methods for estimating specific VLE properties

won't actually be accessible).

Defining an actual model instance using this generic model consists of a number of steps: specifying the process streams that interact with the unit, definining design variables (to allow for analysis and optimisation), defining the equations that describe the unit operation, and defining the equations that can be used for analysis or evaluation (e.g. values used by the criteria definitions). These are described in detail below through the use of a simple example.

The example problem

The problem we wish to consider is the production of HF, as described

in Laing & Fraga (A case study on synthesis in preliminary design,

Computers & Chemical Engineering 21:S53-S58, 1997). Potential

candidate designs for the process need to consider a wide range of

units with varying degrees of detail. The units required include a

kiln (essentially a reactor), an acid blender, an absorber, a quench

unit and distillation. The distillation unit is modelled through the

detailed (albeit short-cut) model available in Jacaranda

(units.vle.Distillation) whereas the others can be represented using

simpler models.

Process streams

There are three types of streams which interact with process units: input (a.k.a. feed) streams, makeup streams (feed streams whose definition depends on the unit operation) and the outputs of the unit. Although makeup streams are really input streams, they differ from input streams in that they are defined as a result of the unit design. The specific input streams, however, will be specified to the unit before the design is attempted.

The kiln unit has one input stream, the main feed, two output streams, the gas stream which is vapour and is the main product of the unit and the waste stream which is in solid phase, and an air make-up stream, of known composition but with the flow rate to be determined by the design model:

use jacaranda.design.units Unit kiln input feed output gas output waste makeup air air

The feed stream will be specified by Jacaranda prior to any design being attempted.

Output streams are created by the Unit model itself. The general

syntax of the output command is:

output NAME [TYPE]

where the square brackets indicate that the type of the output stream

is optional. If specified, this should be a class which implements

the ps.StreamExpressionInterface. If the type is not given, as in the

example above, the system will create a stream of the default type,

units.vle.Stream

The syntax for the makeup command is

makeup NAME INSTANCE

where the instance should be an actual stream which describes the composition of the makeup stream to be used. The amount or rate of that stream will be defined by the design model equations. The air makeup stream definition is

Stream air

phase

components O2 CO2 N2

x 0.20 0.0325 0.7675

vapour

end

end

All streams, whether input, output or makeup, will have variables

available for use in the design equations. The actual variables

defined will depend on the stream definition. For the default base of

units.vle.Stream, the following variables are defined: F, the

amount or flow of the stream; x, the molar or mass composition in

fractions; P, the pressure in atm.; T, the temperature in Kelvin;

and, state, the state of the stream (0 is solid, 1 is liquid and 2

is vapour). For input streams, these variables are defined and set

before the design is evaluated; for output streams, the design

equations should give values to all of these variables as they will

then be used to define the actual output streams. For makeup streams,

the composition, x, will have been defined but all others will be

undefined and should be set by the design model.

Input stream checking

Before attempting a design, Jacaranda will query the unit model to see if the input streams specified are appropriate or not. In other words, the unit will be given a chance to indicate whether the feed streams assigned to the unit are suitable for that unit. The unit does this by specifying a set of conditions for the feed:

feedconditions LOGICAL_EXPRESSION

which, for the kiln example, looks like this:

feedconditions "feed.x[CaF2]>epsilon & feed.x[H2SO4] > epsilon"

This is using the feed input stream defined above and looks to see if

the stream contains any significant amounts of  and

and

.

.

Heat transfer requests

Most units will require heating or cooling (or both). Requests for

heating or cooling are defined using the heat transfer request (HTR)

type in Jacaranda. Such requests are defined using the htr command:

htr NAME

which creates a set of variables for specifying the necessary

information for a heat request, much as stream variables are defined.

The components of a heat transfer request are Q, the duty (in kW with

negative values indicating that heating is required and positive

values indicating that the unit has an excess of heat so cooling is

required); T1, the inlet temperature for the process stream to be

heated or cooled; T2, the outlet temperature of the process stream;

and, U, the heat transfer coefficient  for the process stream side of any exchange.

for the process stream side of any exchange.

For the kiln unit, we define:

htr heat

Design Variables

Design variables are variables which alter the behaviour or design of a unit. These variables are intended for Jacaranda to manipulate, either through the synthesis procedure or through generic optimisation methods within Jacaranda. For the synthesis procedure, it is sufficient to indicate that the variable is of type specification; for the general optimisation use, the variables must also be defined as tunable.

For the kiln unit, we define one such variable:

new specification "Single pass conversion of CaF2" RealSet conversion 0.95 0.96 0.97 0.98 0.99

The general format for defining a new variable is

new FUNCTION DESCRIPTION TYPE NAME VALUES

where FUNCTION is either specification or specification+tunable,

DESCRIPTION is a string which is purely decorative, TYPE is one of

Real, RealSet, Int, IntSet or Component, and VALUES describe the range

of values the variable should consider when used in either synthesis

or optimisation modes. For a RealSet variable, the values are a list

of discrete values. For other types, the values will be specified in

different ways. For instance, for the Real type, the definition would

look like one of the following:

new specification "Continuous design variable" Real x1 VALUE new specification "Continuous design variable" Real x2 MIN MAX N new specification "Continuous design variable" Real x3 VALUE MIN MAX N

In the first case, the variable is given the specified value and the

minimum and maximum values this variable can have are also this

value. This is not particularly useful for design (either for

synthesis or optimisation) but could be useful in debugging. The more

common case is the second where the definition says that ![$x_2 \in

\left [ MIN , MAX \right ]$](ltximg/jacarandablog_371d256bc6dcd655632be3f5e5ad99406a2e16a7.png) .

.

When using the synthesis procedures in Jacaranda, N indicates the

number of discrete values for this variable within the interval

specified. These discrete values will be uniformly distributed across

the interval, including both end-points if  . If a log

based distribution of the discrete points is required, one can use the

. If a log

based distribution of the discrete points is required, one can use the

LogReal type instead of Real.

The final case is the same as the second except that the variable is initialised to have the specific value given which may or may not correspond to one of the discrete values the system would normally use. This will not affect the synthesis procedures but will be useful for the process optimisation methods in Jacaranda.

Design Equations

When Jacaranda wishes to generate a design of the unit, it will

evaluate the equations given using the designequations command. These

equations are evaluated by the jacaranda.util.expr expression

evaluator. This is essentially a vector based calculator and does not

solve a system of simultaneous equations. If solving a complex system

of equations is required, the simple unit model is probably not the

approach one should take for defining the model. Alternative

approaches are beyond the scope of this short note so readers are

encouraged to approach the author for suggestions.

For the kiln model, the following are snippets of the equations we use with some commentary:

designequations # initialize the individual stream flows. we use the feed stream # composition vector to create new vectors of the correct size. gas.f = 0*feed.x waste.f = 0*feed.x feed.f = feed.F*feed.x # feed stream individual component flows

The feed stream will have been defined by Jacaranda and the

appropriate variables (F, x, T, …) defined. These variables are

accessed by the stream name (as given in the input, output and makeup

commands above) followed by the full stop (.) and then the actual

variable name. The expression

feed.f = feed.F*feed.x

creates a vector of feed component flows based on the total flow, F, and the composition, x, of the feed stream.

# the air intake is directly related to the feed stream flow rate air.F = air.ratio * feed.F air.f = air.F * air.x

These equations define the actual amount of the air makeup stream

required. Recall that a makeup stream will have the composition

already defined.

# determine extents of reactions

extent = {0, 0, 0}

if feed.f[CaCO3] > feed.f[H2SO4]

extent[0] = 0

extent[1] = feed.f[H2SO4]

else

extent[1] = feed.f[CaCO3]

if feed.f[CaF2] > (feed.f[H2SO4]-extent[1])

extent[0] = (feed.f[H2SO4]-extent[1])*conversion

else

extent[0] = feed.f[CaF2]*conversion

endif

endif

if feed.f[SiO2] > (4*(extent[0]-feed.f[HF]))

extent[2] = (feed.f[HF]+extent[0])/4

else

extent[2] = feed.f[SiO2]

endif

These equations determine the extends of reaction. There are three reactions and it is important to note that the expression evaluator in Jacaranda uses a zero-based indexing for vectors.

Given the extents of reaction, the output streams can now be defined based on a simple extents of reaction mass balance procedure:

# now define the actual output stream compositions gas.f[H2SO4] = feed.f[H2SO4] - extent[0] - extent[1] gas.f[HF] = feed.f[HF] + 2*extent[0] - 4*extent[2] gas.f[H2O] = extent[1] gas.f[CO2] = extent[1] + air.f[CO2] gas.f[SiF4] = extent[2] gas.f[O2] = air.f[O2] gas.f[N2] = air.f[N2] gas.F = $gas.f # total gas flow gas.x = gas.f/gas.F # and actual composition gas.T = feed.T gas.P = feed.P gas.state = vapour waste.f[CaF2] = feed.f[CaF2] - extent[0] waste.f[CaCO3] = feed.f[CaCO3] - extent[1] waste.f[SiO2] = feed.f[SiO2] - extent[2] waste.f[CaSO4] = extent[0] + extent[1] waste.F = $waste.f # total waste stream flow waste.x = waste.f/waste.F # and composition waste.T = feed.T waste.P = feed.P waste.state = solid

Note the use of the $ operator which means sum of all elements of the

vector to calculate the total flow of the gas and waste streams.

Given the specifications on the output streams, we can now design the actual physical unit. This includes a simple quadrature rule for evaluating an integral numerically:

# finally, design the actual reactor which is based on a numerical # integration, as described above. nsteps = 100 N = 2/3 M = 1/3 k450 = 0.247 E = 38363 k = k450 * exp(-1 * E * (1/feed.T - 1/450)/R) Xf = conversion Xo = preconversion # preconversion Rc = feed.f[CaF2]/(feed.f[CaF2]+feed.f[CaCO3]) # CaF2:CaCO3 ratio Ra = (feed.f[H2SO4]-extent[1])/feed.f[CaF2] # Acid:CaF2 ratio dX = (Xf-Xo)/nsteps rio = (1.0 - (1.0-Xo)^M) / ( k*(Rc*Rc*(Ra-Xo)*(Ra-Xo)*(1.0-Xo)^N) ) X = Xo + dX t = 0 # residence time in minutes while X <= Xf ri = (1.0 - (1.0-X)^M) / ( k*(Rc*Rc*(Ra-X)*(Ra-X)*(1.0-X)^N) ) t = t + dX*(ri+rio)/2 rio = ri X = X + dX endwhile volume = feed.F*t*60 # remember to convert to seconds diameter = (volume*4/(Pi*htod))^(1/3) height = diameter*htod

Finally, given the extents of reaction, we can solve the energy balance equations to tell us the amount of heating or cooling required. The numbers calculated are used to define a heat transfer request (HTR) which was defined above:

# now calculate the heat balance; recall that Q for a heat

# transfer request will have a positive value for cooling and a

# negative value if heating is required so we need to negate the value

# we get from the heats of reaction directly.

# values in the next equation are heats of reaction [kJ/kmol]

heat.Q = - extent*{53.7, 91.1, -189.4}

heat.T1 = feed.T

heat.T2 = feed.T

heat.P = feed.P

heat.U = 1

end # of design equations

Evaluation equations

Once the design has been generated, Jacaranda will evaluate the model equations which will typically be used to give values to the variables used to evaluate the criteria for comparing alternative process designs and for optimisation. These variables will be problem dependent. For the kiln model, the only variable we need is the capital cost of the unit:

model

capcost = 1917 * diameter^1.066

end

end # of Unit kiln definition

[1] In this blog, class names are typically abbreviated by removing

the leading jacaranda.design. prefix. Unless otherwise

noted, all classes should have this prefix to be fully qualified.

The full example model definition

The complete model definition, comprising all the pieces described above, can be found here:

# -*- text -*-

#

# Unit model definition for the HF case study.

# Eric S Fraga

# $Id: kiln.in 2 2004-04-17 20:20:23Z ucecesf $

use jacaranda.design.units

# the air makeup stream used by the unit below

Stream air

phase

components O2 CO2 N2

x 0.20 0.0325 0.7675

vapour

end

end

# The kiln is essentially a reactor. There are three reactions:

#

# CaF2 + H2SO4 -> 2 HF + CaSO4 Hr = 53.7

# CaCO3 + H2SO4 -> CO2 + H20 Hr = -91.1

# SiO2 + 4 HF -> SiF4 + 2 H2O Hr = -189.4

#

# The model is again essentially a simple mass balance. There are two

# product streams (HF off-gas and solid waste), one feed stream and

# one make up stream (air intake)

#

# The size of the reactor is estimated by first estimating the

# residence time based on the following model (from Laing & Fraga, 1997):

#

# -----------------------------------------------------------------

# Reactor Residence Time

# ----------------------

# From internal report (see jwp)

# dX/dt = r = k (Rc^2*(Ra-X)^2*(1-X)^N / (1 - (1-X)^M)

#

# X = conversion of CaF2,

# Rc = mol of CaF2 per mol of Ca in fluorspar feed.

# Ra = acid:spar ratio

# k = rate constant

# N & M are constants dependent on rate model

#

# The rate constant is given by

# k(T) = k(450) exp(-E*(1/T -1/450)/R)

#

# R = 8.3143 kJ/kmolK

# Rate models : N : M : k(450) (min^-1X^-2) : E (kj/kmol)

# 9 2/3 1/3 0.247 38,263

# 10 1/3 1/3 0.166 35,379

#

# Use simpsons rule to integrate dX/r from prereactor conversion(Xo)

# to final conversion (X).

#

# Use rate model 9, for the sake of argument!

#

# Note: residence time is in minutes!

#

# ----------------------------------------------------------------

vle.Separator kiln

# make sure we can control the number of occurences of this unit

limit

new specification "Single pass conversion of CaF2" RealSet conversion 0.95 0.96 0.97 0.98 0.99

new input "Reactor height/length to diameter ratio" Real htod 6.5

new input "Pre-reactor conversion" Real preconversion 0.3

new input "Ratio of air to feed" Real air.ratio 0.05

output gas vapour

output waste solid

makeup air air

htr heat

#

# must ensure that we have some CaF2 in the feed stream

#

feedconditions "feed.x[CaF2]>epsilon & feed.x[H2SO4] > epsilon"

# now the design equations which include defining the extents of the

# reactions and the actual sizing information for the unit

design

# initialize the individual stream flows. we use the feed stream

# composition vector to create new vectors of the correct size.

gas.f = 0*feed.x

waste.f = 0*feed.x

feed.f = feed.F*feed.x # feed stream individual component flows

# the air intake is directly related to the feed stream flow rate

air.F = air.ratio * feed.F

air.f = air.F * air.x

# determine extents of reactions

extent = {0, 0, 0}

if feed.f[CaCO3] > feed.f[H2SO4]

extent[0] = 0

extent[1] = feed.f[H2SO4]

else

extent[1] = feed.f[CaCO3]

if feed.f[CaF2] > (feed.f[H2SO4]-extent[1])

extent[0] = (feed.f[H2SO4]-extent[1])*conversion

else

extent[0] = feed.f[CaF2]*conversion

endif

endif

if feed.f[SiO2] > (4*(extent[0]-feed.f[HF]))

extent[2] = (feed.f[HF]+extent[0])/4

else

extent[2] = feed.f[SiO2]

endif

# now define the actual output stream compositions

gas.f[H2SO4] = feed.f[H2SO4] - extent[0] - extent[1]

gas.f[HF] = feed.f[HF] + 2*extent[0] - 4*extent[2]

gas.f[H2O] = extent[1]

gas.f[CO2] = extent[1] + air.f[CO2]

gas.f[SiF4] = extent[2]

gas.f[O2] = air.f[O2]

gas.f[N2] = air.f[N2]

gas.F = $gas.f # total gas flow

gas.x = gas.f/gas.F # and actual composition

gas.T = feed.T

gas.P = feed.P

waste.f[CaF2] = feed.f[CaF2] - extent[0]

waste.f[CaCO3] = feed.f[CaCO3] - extent[1]

waste.f[SiO2] = feed.f[SiO2] - extent[2]

waste.f[CaSO4] = extent[0] + extent[1]

waste.F = $waste.f # total waste stream flow

waste.x = waste.f/waste.F # and composition

waste.T = feed.T

waste.P = feed.P

# finally, design the actual reactor which is based on a numerical

# integration, as described above.

nsteps = 100

N = 2/3

M = 1/3

k450 = 0.247

E = 38363

k = k450 * exp(-1 * E * (1/feed.T - 1/450)/R)

Xf = conversion

Xo = preconversion # preconversion

Rc = feed.f[CaF2]/(feed.f[CaF2]+feed.f[CaCO3]) # CaF2:CaCO3 ratio

Ra = (feed.f[H2SO4]-extent[1])/feed.f[CaF2] # Acid:CaF2 ratio

dX = (Xf-Xo)/nsteps

rio = (1.0 - (1.0-Xo)^M) / ( k*(Rc*Rc*(Ra-Xo)*(Ra-Xo)*(1.0-Xo)^N) )

X = Xo + dX

t = 0 # residence time in minutes

while X <= Xf

ri = (1.0 - (1.0-X)^M) / ( k*(Rc*Rc*(Ra-X)*(Ra-X)*(1.0-X)^N) )

t = t + dX*(ri+rio)/2

rio = ri

X = X + dX

endwhile

volume = feed.F*t*60 # remember to convert to seconds

diameter = (volume*4/(Pi*htod))^(1/3)

height = diameter*htod

# now calculate the heat balance; recall that Q for a heat

# transfer request will have a positive value for cooling and a

# negative value if heating is required so we need to negate the value

# we get from the heats of reaction directly.

heat.Q = - extent*{53.7, 91.1, -189.4} # values are heats of reaction [kJ/kmol]

heat.T1 = feed.T

heat.T2 = feed.T

heat.P = feed.P

heat.U = 1

end # of design equations

# cost model

model

capcost = 1917 * diameter^1.066

end

print

end

# add this unit to the list of units available for process flowsheet

# generation

edit globalData

unit kiln

end

This model is copyright Eric S Fraga, all rights reserved. Distribution and use not allowed without his permission.